NEWS

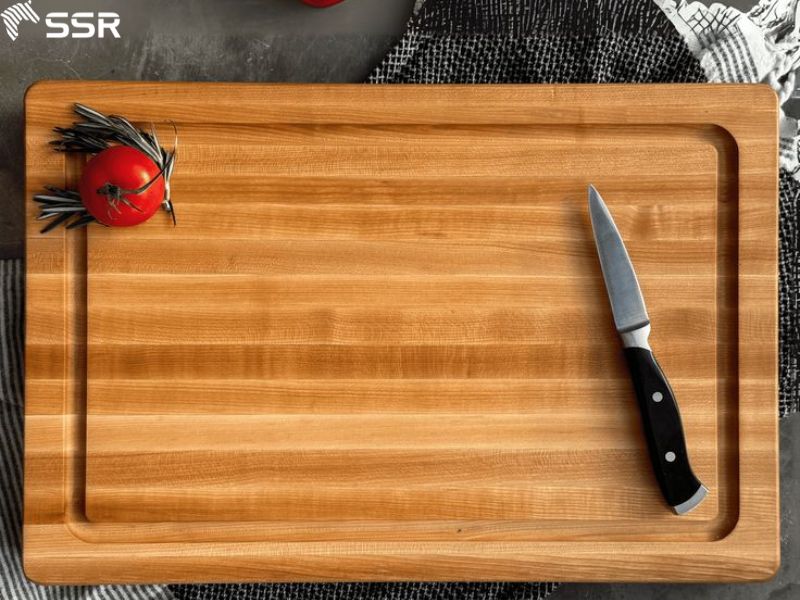

A wood cutting board is more than just a kitchen tool – it’s a staple for home cooks and professional chefs alike. Known for its durability, aesthetics, and knife – friendly surface, a wooden cutting board offers a classic yet practical solution for daily food prep.

In this blog, we’re excited to share practical knowledge and insider tips gathered from our team of experienced woodworkers, engineers, and global buyers. Whether you’re sourcing for retail, wholesale, or simply curious about wooden cutting boards, you’ll find valuable insights right here – straight from the experts in the industry.

What is the Purpose of a Wood Cutting Board?

What is the purpose of a wood cutting board

The primary purpose of a wooden cutting board is to provide a stable, sanitary surface for chopping, slicing, and dicing ingredients. It protects your countertops from knife damage and helps maintain the sharpness of your blades. Many also double as elegant serving boards for cheese, bread, or charcuterie, making them both functional and decorative.

Unlike plastic alternatives, wooden cutting boards offer a tactile, knife-friendly surface that reduces wear on your blades. This is especially important for chefs and home cooks who prepare meals daily and want to keep their knives in top condition.

In professional kitchens and homes alike, a wood cutting board serves as a central workspace for food prep. Its natural texture provides grip, preventing ingredients from slipping while cutting. And because wood has slight self-healing properties, light knife marks tend to close over time, extending the life of the board and keeping it looking clean.

Furthermore, hardwoods like maple and acacia used in wooden boards are naturally resistant to bacteria, provided they’re cleaned and maintained properly. This makes wooden boards a smart, hygienic choice when cared for correctly.

What Type of Wood is Best for Cutting Boards?

What type of wood is best for cutting boards

Choosing the right wood is essential when selecting a high-quality wooden cutting board. The best types of wood offer a balance between hardness, durability, food safety, and knife preservation. Below are some of the top choices used by professionals and manufacturers alike:

Maple

Maple wood cutting board

Maple, especially hard maple (also known as sugar maple), is a favorite in both commercial and home kitchens. It’s a closed-grain hardwood, meaning it has tiny pores that prevent bacteria and moisture from seeping in. Maple is hard enough to withstand daily chopping, yet soft enough to be gentle on knife edges – making it one of the best all-around choices for a wood cutting board.

Walnut

Walnut wood chopping board

Walnut is prized for its rich, dark color and smooth texture. While slightly softer than maple, it still holds up well to regular use and is kind to knife blades. Many chefs prefer walnut boards for their aesthetic appeal and comfortable cutting experience.

Teak

Teak wood cutting board

Teak is naturally infused with oils and silica, which makes it highly resistant to moisture, rot, and warping – ideal for use in humid climates or busy kitchens. Though teak is slightly harder on knives compared to maple or walnut, its low maintenance and durability make it a popular option for premium wooden cutting boards.

Acacia

Acacia wood cutting board

Acacia is a budget-friendly hardwood that doesn’t compromise on performance. Known for its striking grain patterns and natural durability, acacia is commonly used in both cutting and serving boards. It’s harder than maple, so it may wear down knives faster over time, but it’s a great choice for those looking for an attractive and sturdy option at a lower price point.

Cherry

Cherry wood cutting board

Cherry wood develops a warm, reddish tone as it ages, giving your wood cutting board a beautiful, timeless look. It’s slightly softer than maple, which makes it gentle on knives, though it may show wear more quickly. Still, it remains a solid choice for those who value aesthetics and craftsmanship.

What Are the Benefits of a Chopping Board?

What are the benefits of a chopping board

Using a high-quality wood cutting board brings many benefits:

- Gentle on knife edges

- Durable and long-lasting

- Naturally antimicrobial (in certain hardwoods)

- Adds rustic charm to your kitchen

- Versatile – from prep to presentation

How Do I Choose a Wooden Cutting Board?

How do I choose a wooden cutting board

With years of experience manufacturing and exporting wood cutting boards, we know that a good cutting board is a thoughtful combination of proper wood selection, construction techniques, and a deep understanding of the end user’s needs.

1. Wood Type

Always go for hardwoods, dense and durable species that resist knife marks and bacterial growth. Top choices include:

- Maple: closed-grain, naturally antibacterial, and highly durable.

- Walnut: softer on blades, rich in color, and visually striking.

- Teak: naturally oily and moisture-resistant, ideal for humid environments.

- Acacia: tough and affordable with beautiful grain patterns.

- Cherry: softer, gentle on knives, and darkens beautifully with age.

Avoid softwoods (like pine) or any wood that contains toxic oils not suitable for food contact.

2. Grain Orientation

- End Grain: Premium choice. The vertical wood fibers allow knives to sink between the grains, reducing wear on blades and allowing the board to “self-heal” from knife marks.

- Edge Grain: More common and budget-friendly. Offers good durability and is easier to maintain.

3. Size & Thickness

Choose a size that fits your kitchen and cooking needs:

- Home kitchens: 14”x10” to 16”x12” is ideal. Thickness of wood cutting board should be at least 1” (2.5 cm) for stability.

- Professional use: Go for larger, thicker boards with rubber feet or handles for grip.

- Dual-use (cutting & serving): Consider mid-sized boards with a round shape or handle for presentation.

4. Juice Groove

If you cut meat or juicy fruits regularly, a juice groove helps prevent liquid from spilling over, keeping your countertop clean.

5. Surface Finish & Maintenance

Choose boards treated with food-safe mineral oil or beeswax to protect against moisture and cracking. Regular oiling helps preserve the board’s look and extends its life.

Read more: Instructions on how to choose a good wooden cutting board for the kitchen

What Should You Not Cut on a Wood Cutting Board?

While wooden cutting boards are prized for their beauty, durability, and gentleness on knives, there are some foods you should avoid cutting on them especially for hygiene and maintenance reasons.

1. Raw Meat, Poultry, or Seafood

What should you not cut on a wood cutting board

- Why to avoid: Raw animal proteins carry bacteria like Salmonella, E. coli, and Listeria, which can seep into the porous surface of wood.

- Even though hardwoods like acacia have natural antimicrobial properties, deep cuts or prolonged moisture can allow bacteria to grow in the grain.

- What to do instead: Use a plastic or composite board for raw meats, which can be sanitized in the dishwasher.

2. Very Juicy or Acidic Foods (e.g., Pineapple, Tomatoes, Citrus)

Wipe the cutting board after cut juicy fruits

- Why to avoid: Acidic juices can degrade the wood over time, leaving stains or causing the surface to warp.

- Excess moisture may also soak in and increase the risk of splitting or mold if not dried properly.

- Tip: If you do cut juicy fruits, wipe the board immediately and dry it thoroughly.

3. Foods with Strong Odors (e.g., Garlic, Onions, Fish)

Wood can absorb strong smells, which may linger and transfer

- Why to avoid: Wood can absorb strong smells, which may linger and transfer to other foods especially if you’re slicing fruit or bread next.

- Tip: Use a separate board or clean your wood board thoroughly with lemon and salt after cutting odor-rich foods.

4. Raw Dough or Pastry

Can I use vinegar on a wood cutting board

- Why to avoid: Sticky dough can cling to the wood cutting board surface and fill in knife grooves or natural cracks. It’s hard to clean without using excess water, which isn’t ideal for wood.

- What to do instead: Use a smooth, nonporous surface like marble, plastic, or a dedicated pastry mat.

5. Chopping with Heavy Force (e.g., Butchering Bones)

What are the problems with wooden cutting boards

- Why to avoid: Repeated heavy chopping can damage the board by creating deep grooves that harbor bacteria and weaken the structure.

- What to do instead: Use a butcher block or a synthetic chopping board specifically designed for cleaving.

How to Clean a Wooden Cutting Board?

How to clean a wooden cutting board

Cleaning your wood cutting board properly is crucial not just for hygiene but also for maintaining its durability and appearance. Unlike plastic boards, wood requires a bit more care but with the right routine, your board can last for years while staying safe and beautiful.

- Rinse Immediately After Use

As soon as you finish chopping, rinse the board under warm running water to remove food residue. This helps prevent stains and keeps odors from settling into the wood grain.

2. Scrub with Mild Soap and Warm Water

Use a soft sponge or brush with mild dish soap and warm water to gently scrub the surface. Avoid harsh scrubbers, which can damage the finish or gouge the surface.

3. Never Soak or Use the Dishwasher

Do not soak your wood chopping board

Do not soak your wood cutting board in water or put it in the dishwasher both can cause the board to absorb excess moisture, leading to swelling, cracking, or warping. Wood is porous, and prolonged exposure to water will ruin it over time.

4. Disinfect Occasionally with Natural Solutions

To kill bacteria naturally, use white vinegar or a mixture of lemon and coarse salt.

- Vinegar method: Spray undiluted white vinegar over the surface and wipe clean.

- Lemon-salt method: Sprinkle salt, rub with a halved lemon in circular motions, then rinse and dry.

These methods deodorize, sanitize, and lift surface stains without damaging the wood.

5. Dry Upright or with Air Circulation

After cleaning, dry the board upright or lean it against a wall to let air circulate around both sides. Never leave it flat on a wet countertop that invites warping.

6. Oil Monthly to Maintain

Oil monthly to maintain wood cutting board

At least once a month (or more with heavy use), treat your wood cutting board with food-grade mineral oil or a specialized cutting board conditioner.

- Warm the oil slightly before application.

- Apply generously with a clean cloth or paper towel.

- Let it absorb for a few hours or overnight, then wipe off excess.

Oiling helps seal the pores, repels moisture, and keeps the wood from drying out or cracking.

Pro Tip: Always clean both sides of the board even if you only used one side. This keeps moisture balanced and prevents uneven warping.

How to Make Wood Cutting Boards?

SSR VINA has standardized a 12-step manufacturing process for high-quality wood cutting boards (example for this manufacturing process is acacia wood). This process ensures precision, durability, food safety, and aesthetic appeal – all vital qualities for demanding international markets such as the USA, Europe, and Asia.

1. Raw Material Selection

We source Acacia wood from sustainable plantations with legal and FSC-certified origins. Logs are inspected for age (ideally 7 – 10 years old), moisture content, grain pattern, and free from defects like knots, cracks, or insect damage. Only high-grade logs are approved for cutting.

2. Cutting the Lumber

Logs are processed into planks using industrial sawmills. Each plank is cut to specific thickness and width based on the product design. Our operators ensure precise dimensions to facilitate flawless edge-gluing later on.

3. Gluing & Laminating

Planks are edge-jointed using non-toxic, food-grade adhesive. The glued pieces are pressed under hydraulic pressure to form large, durable panels. We control temperature, glue quantity, and clamping pressure to prevent delamination and ensure long-term structural integrity.

4. Planing & Squaring Up

The laminated panels are fed into thickness planers to smooth out the surface and reduce to exact target thickness. We also use jointers and panel saws to square the panels, ensuring each piece has straight, clean edges and is ready for shaping.

5. Cutting Off the Corners

Depending on the design specifications, we trim the corners into round or chamfered shapes using precision band saws or CNC routers. This step enhances user safety and visual appeal.

6. Initial Sanding (Coarse)

The boards undergo a first round of sanding using orbital or belt sanders. We typically begin with 80 – 100 grit sandpaper to remove any surface glue residue, blade marks, or rough patches.

7. Edge Rounding

Using routing machines, we round the edges of the cutting boards to achieve a smooth, soft touch. This is essential for ergonomic handling and gives the product a refined, premium look.

8. Finish Sanding

We perform fine sanding using 180 – 220 grit sandpaper for a smooth, silky surface. This ensures that the cutting board is pleasant to touch and free from splinters or surface imperfections. The finish must be flawless before oiling.

9. Oil Finishing

Each board is hand-finished with food-safe mineral oil or natural plant oils (e.g., coconut or linseed oil). This enhances the wood’s natural color, adds water resistance, and protects against bacteria and mold. For premium models, a beeswax coating is added for extra sheen and protection.

10. Grading & Quality Control

Each cutting board is manually inspected by our quality assurance team. We evaluate:

- Glue integrity and bonding strength

- Moisture content

- Flatness and surface texture

- Aesthetic qualities: wood grain, color uniformity, edge consistency. Boards are classified into Grade A (export quality), Grade B (local market or second line), and rework/rejects.

11. Packaging

Approved boards are cleaned, labeled, and carefully packaged. We use kraft wrap, shrink film, or individual cartons, depending on the client’s request. Each unit includes usage instructions, care guidelines, and product barcode for traceability.

- Shipping & Export

Finally, finished wood cutting boards are palletized, container-loaded, and shipped from our factory to ports worldwide. Our logistics team ensures proper documentation (CO, Packing List, Invoice, Fumigation Certificate) and timely delivery to meet the customer’s schedule.

You can see our Premium Wooden Cutting Board at here

FAQs

Wooden cutting board

Why Do Chefs Prefer Wooden Cutting Boards?

Chefs love wooden cutting boards because they’re gentle on knives, provide a stable cutting surface, and last for years with proper care.

Do Wooden Cutting Boards Hold Bacteria?

Studies show that certain hardwoods like maple have natural antimicrobial properties. While bacteria can enter knife grooves, regular cleaning and drying prevent bacterial buildup.

What Woods to Avoid for Cutting Boards?

Avoid softwoods like pine, cedar, and fir – they dent easily and can release resins. Also, steer clear of exotic woods with toxic oils or allergens.

What Are the Problems With Wood Cutting Boards?

- Requires regular oiling

- Can warp or crack if soaked

- Not ideal for raw meat unless sanitized properly

- Heavy and less portable than plastic boards

How Long Does a Wooden Cutting Board Last?

How long does a wooden cutting board last

With proper care, a high-quality wood cutting board can last 5 to 10 years or more. Some even become family heirlooms.

Do You Wash Wooden Cutting Board After Every Use?

Yes. Always wash your wood cutting board after each use to remove food particles, stains, and bacteria.

Can I Use Vinegar on a Wood Cutting Board?

Absolutely yes. White vinegar is a safe, natural disinfectant that can clean and deodorize your board. Just avoid prolonged soaking.

How can I get the price?

To get a price, please tell us about the product, quantity, and any customization. We’ll send you a quote. Our sales team will contact you shortly . For urgent requests, please feel free to contact us directly via email or hotline.

Can you make products from our designs?

Yes, we do OEM and ODM.

What is your MOQ?

Our minimum order quantity is one 20ft container.

SSR VINA – Your Trusted Wood Chopping Boards Supplier

SSR VINA your trusted wood chopping boards supplier

If you’re looking for a high-quality, durable, and eco-friendly wood cutting board, SSR VINA is the ideal place to buy. As a leading manufacturer and exporter of solid wood products in Vietnam, SSR VINA specializes in producing chopping boards made from sustainably sourced acacia, teak and rubber wood.

Each board is crafted through a strictly controlled process from raw material selection to final oil finishing ensuring food safety, longevity, and beautiful natural wood grain. With FSC-certified wood, customizable designs, and bulk export capabilities, SSR VINA is a trusted supplier for both household users and global retailers. Choosing SSR VINA means choosing craftsmanship, quality, and sustainability.

Conclusion

A wood cutting board isn’t just a kitchen essential – it’s a long-term investment in both function and style. Whether you’re slicing veggies or serving charcuterie, the right wood cutting board enhances your cooking experience and protects your tools.

Ready to upgrade your kitchen? Choose a board that suits your cooking habits and maintain it well – it will serve you for years to come.

Featured Products

Acacia Wood Butcher Block Countertops Supplier

Specifications:

- Species: Acacia

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 30-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Birch Butcher Block Countertop Supplier

Specifications:

- Species: Birch

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Featured News

Related News

SSR at Hawa Expo 2026: Scaling excellence to global markets

Consistency in the global wood industry is the result of large-scale capacity and meticulous coordination. SSR is proud to announce our official participation in HAWA EXPO 2026, driven by a serious commitment to showcase the strength of our integrated ecosystem. This event is a milestone for us to prove that enterprises can fully master the […]

Why Moisture Consistency Defines Export-Grade Wood Panels?

Moisture content is one of the most critical yet often underestimated factors in wood panel manufacturing. For export grade rubberwood panels, precise moisture control is a structural requirement that determines long term stability. Understanding how moisture behaves and how it is managed at scale is essential for any serious bulk buyer. 1. What Is Wood […]