NEWS

Moisture content is one of the most critical yet often underestimated factors in wood panel manufacturing. For export grade rubberwood panels, precise moisture control is a structural requirement that determines long term stability. Understanding how moisture behaves and how it is managed at scale is essential for any serious bulk buyer.

1. What Is Wood Moisture Content?

Wood moisture content (MC) is the amount of water contained inside wood, expressed as a percentage of its dry weight.

Fresh rubberwood typically contains 35–45% moisture content. Before it can be used for panel manufacturing, this moisture must be reduced through kiln drying.

After drying, wood manufacturers generally lower the moisture to below 12%. For export-grade rubberwood panels, the target range is tighter: 8–10% moisture content, stabilized within ±1% tolerance.

Moisture content is not just a number; it directly affects how wood behaves during processing and after installation.

SSR staff are putting the wood in the drying machine after sawing

2. Why Is Wood Moisture Content Important in Panel Manufacturing?

Wood is a hygroscopic material. It absorbs and releases moisture depending on the surrounding environment.

When the Panel Is Too Wet (High Moisture Content):

- Excess moisture causes the panel to absorb water, leading to swelling, warping, and deformation.

- It can result in glue line failure or delamination, especially during lamination or surface pressing.

- Increases the risk of mold growth, affecting both product durability and user health.

- Reduces adhesive bonding strength, making surface layers uneven or prone to peeling

The board warps when the humidity is too high

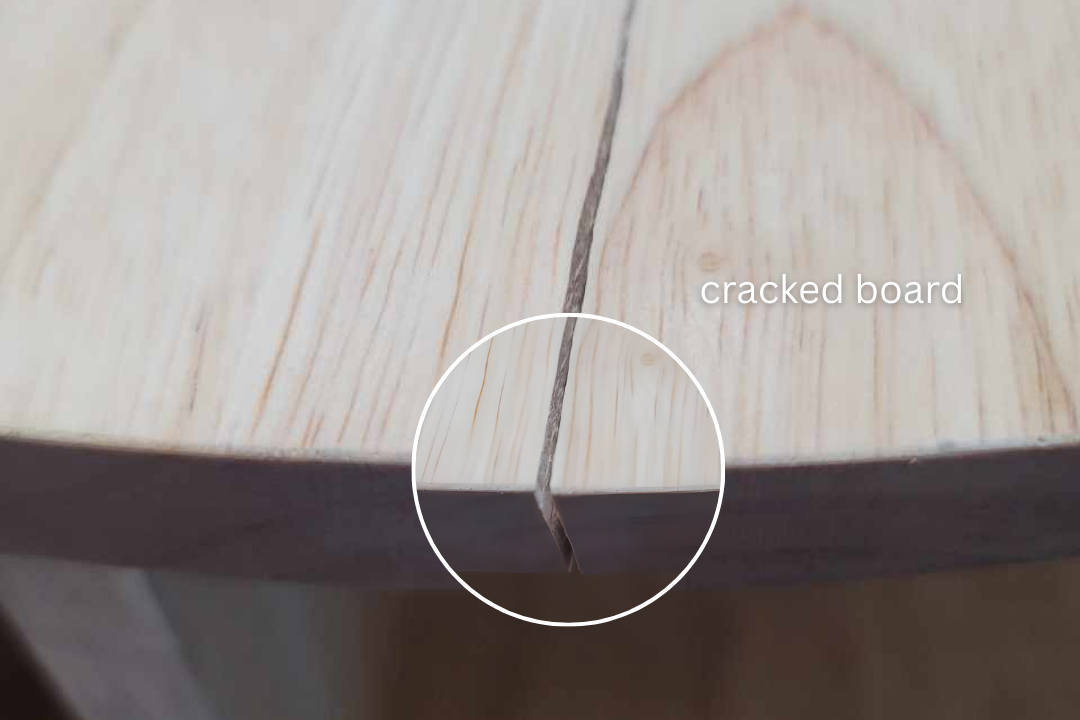

When the Panel Is Too Dry (Low Moisture Content):

- The panel becomes more prone to cracking and shrinkage, especially when exposed to higher humidity environments.

- Can cause glue line cracking, particularly on detailed parts or edge profiles.

- Reduces overall dimensional stability after finishing.

- It is harder to control during further processing, such as cutting, edge banding, or coating

The wooden plank is cracked

In large-format rubberwood panels, small inconsistencies between slats can create internal stress once glued together.

For export shipments that move across different climate zones, unstable moisture content increases the risk of deformation during transport or in the final service environment.

This is why professional wood manufacturers treat moisture control as a structural requirement, not a secondary inspection step.

3. What Is the Ideal Moisture Content for Export-Grade Wood Panels?

The correct moisture level depends on the destination market’s climate. Wood continuously adjusts to the surrounding air according to its Equilibrium Moisture Content (EMC).

For climate-controlled interiors in markets such as the EU, UK, and US, wood panels are typically stabilized at 8–10% moisture content with ±1% variation between components.

Consistency is critical. Even when the average moisture is correct, uneven distribution within the panel can still cause long-term instability.

4. How Do Professional Wood Manufacturers Control Moisture at Scale?

Industrial wood manufacturers integrate moisture control into multiple production stages. At SSR, moisture is monitored:

- After kiln drying

- Before finger-jointing

- Before panel gluing

- Overall inspection of pre-processing before warehousing

SSR QC measures humidity after kiln drying

Materials outside the acceptable range are separated and reconditioned. This ensures uniform moisture content across high-volume orders, including container-scale shipments.

Industrial control differs from small-scale production because consistency must be maintained across thousands of square meters — not just individual samples.

SSR QC conducts a comprehensive inspection before warehousing

5. Why Should Bulk Buyers Care About Wood Moisture Content?

For importers, OEM factories, and wholesalers, improper moisture control can result in:

- Product claims

- Container rejection

- Installation delays

- Long-term brand damage

By sourcing from experienced wood manufacturers that adhere to controlled 8–10% moisture standards, buyers reduce downstream risks and improve product reliability in their markets.

When evaluating a wood panel supplier, buyers should verify the target moisture range and the supplier’s ability to consistently control tolerances. It is also essential to assess whether a multi-stage inspection process is in place and whether the manufacturer can maintain stable quality across bulk production, ensuring reliable performance in large-volume orders.

SSR – Your Trusted B2B Partner

SSR specializes in export-grade rubberwood panels with controlled wood moisture content designed for international markets.

View SSR’s verified manufacturing profile and bulk supply capability on our official Alibaba store and contact our team to discuss your upcoming wood panel requirements.

Featured Products

Acacia Wood Butcher Block Countertops Supplier

Specifications:

- Species: Acacia

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 30-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Birch Butcher Block Countertop Supplier

Specifications:

- Species: Birch

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Featured News

Related News

SSR at Hawa Expo 2026: Scaling excellence to global markets

Consistency in the global wood industry is the result of large-scale capacity and meticulous coordination. SSR is proud to announce our official participation in HAWA EXPO 2026, driven by a serious commitment to showcase the strength of our integrated ecosystem. This event is a milestone for us to prove that enterprises can fully master the […]

SSR Welcomes China Wood Protection Industry Association to Strengthen Vietnam-China Wood Cooperation

SSR recently had the honor of welcoming a delegation from the China Wood Protection Industry Association, led by Mr. Chongyu Li, for a strategic exchange at our office in Ho Chi Minh City, Vietnam. The visit reflects the growing collaboration between Vietnam and China’s wood industries, particularly in sustainable sourcing, customized manufacturing, and long-term supply […]