Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

MOQ: 1 container 20ft (18-23cbm)

Related Products

About This Item

Dimensions

Quality Face

Face A:

| Face C:

|

Face A Rubberwood Finger Joint Board |  Face C Rubberwood Finger Joint Board |

Quality Grade

AA Grade:

| AC Grade:

|

AA Grade Rubberwood Finger Joint Board |  AC Grade Rubberwood Finger Joint Board |

Quality Inspection

We maintain strict quality control processes to build long-term trust with our partners and reinforce our brand position in the market

Packing & Container Loading

We take packing seriously, from stacking to container loading, every step is handled with care and precision to protect product quality and meet global shipping standards.

Dimensions

Quality Face

Face A:

|

Face A Rubberwood Finger Joint Board |

Face C:

|

Face C Rubberwood Finger Joint Board |

Quality Grade

AA Grade:

|

AA Grade Rubberwood Finger Joint Board |

AC Grade:

|

AC Grade Rubberwood Finger Joint Board |

Quality Inspection

We maintain strict quality control processes to build long-term trust with our partners and reinforce our brand position in the market.

Packing & Container Loading

We take packing seriously, from stacking to container loading, every step is handled with care and precision to protect product quality and meet global shipping standards.

SSR VINA – Rubberwood Finger Joint Board SupplierLooking for a reliable Rubberwood finger joint board supplier? SSR VINA offers top-tier wholesale solutions, perfect for furniture production, interior applications, and construction. Our boards are known for their durability, stability, and eco-friendliness, making them a sustainable choice for global markets. |  |

| Advantages Of Rubberwood (Hevea) Finger Joint Boards

Finger joint wood board is made from small pieces of plantation wood that are bonded “finger joint” together using adhesives and subjected to high pressure and heat. Through an advanced manufacturing process, finger joint board wood is a material that surpasses the limitations of solid wood, offering an optimized solution for construction and interior needs.

|

Applications

SSR VINA offers wholesale pricing for Rubberwood Finger Joint Board made in Vietnam, providing businesses with affordable, high-quality solutions for their projects. Let us help you achieve the perfect finishing detail for your wood flooring and handrail designs!

Bedroom

Living Room

Manufacturing Center

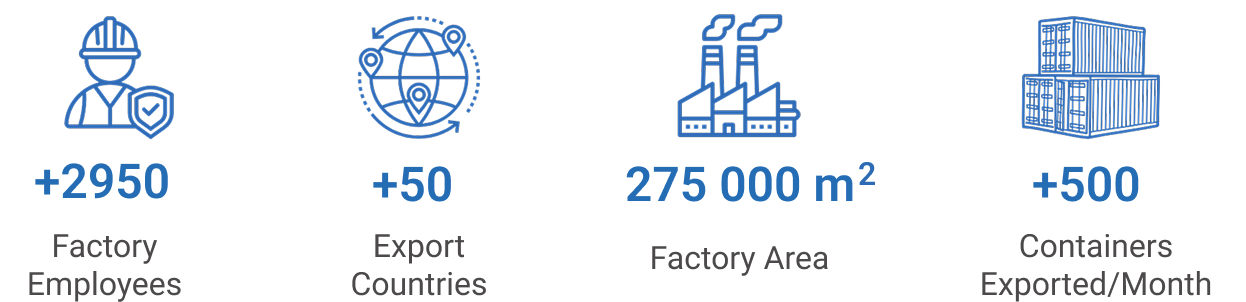

Our Advantages

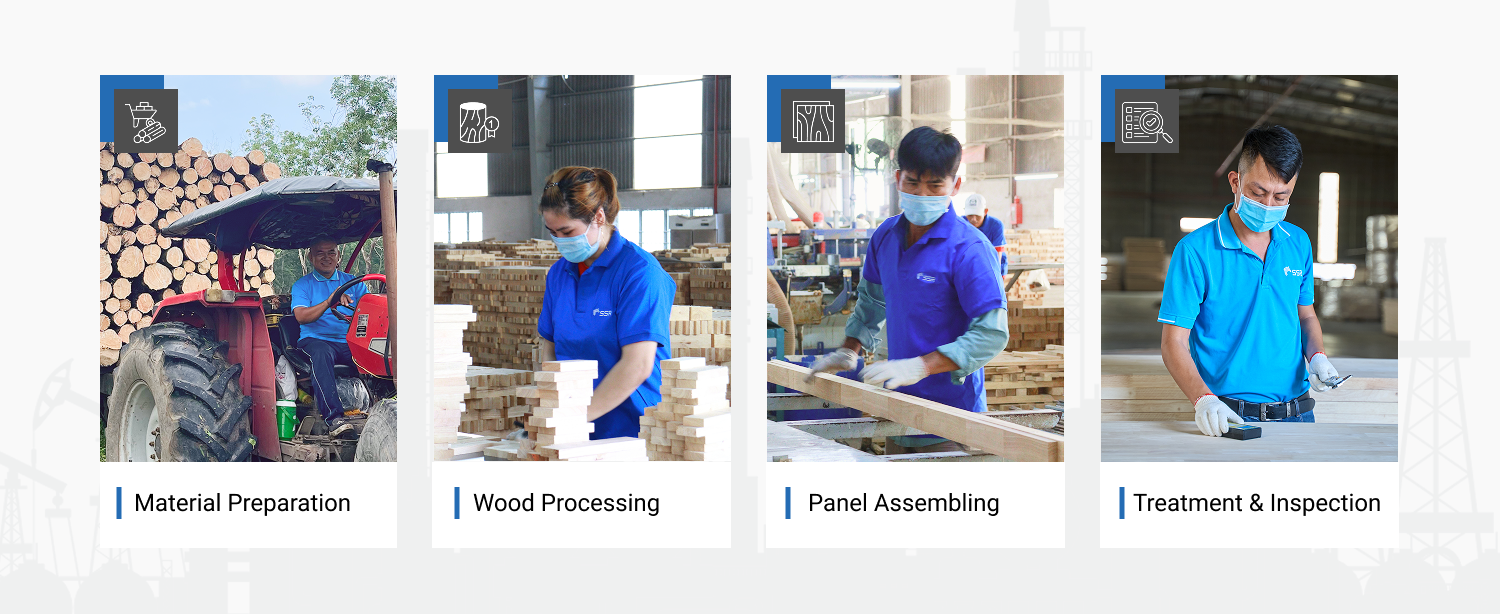

Manufacturing Process

SSR VINA – Rubberwood Finger Joint Board SupplierLooking for a reliable Rubberwood finger joint board supplier? SSR VINA offers top-tier wholesale solutions, perfect for furniture production, interior applications, and construction. Our boards are known for their durability, stability, and eco-friendliness, making them a sustainable choice for global markets. |

|

Advantages Of Rubberwood (Hevea) Finger Joint Boards

Finger joint wood board is made from small pieces of plantation wood that are bonded “finger joint” together using adhesives and subjected to high pressure and heat. Through an advanced manufacturing process, finger joint board wood is a material that surpasses the limitations of solid wood, offering an optimized solution for construction and interior needs. |

|

Applications

SSR VINA offers wholesale pricing for Rubberwood Finger Joint Board made in Vietnam, providing businesses with affordable, high-quality solutions for their projects. Let us help you achieve the perfect finishing detail for your wood flooring and handrail designs!

Bedroom

Living Room

Manufacturing Center

Our Advantages

Manufacturing Process

Contact Us

Get A Quote

Customers Also Considered

Customers also considered