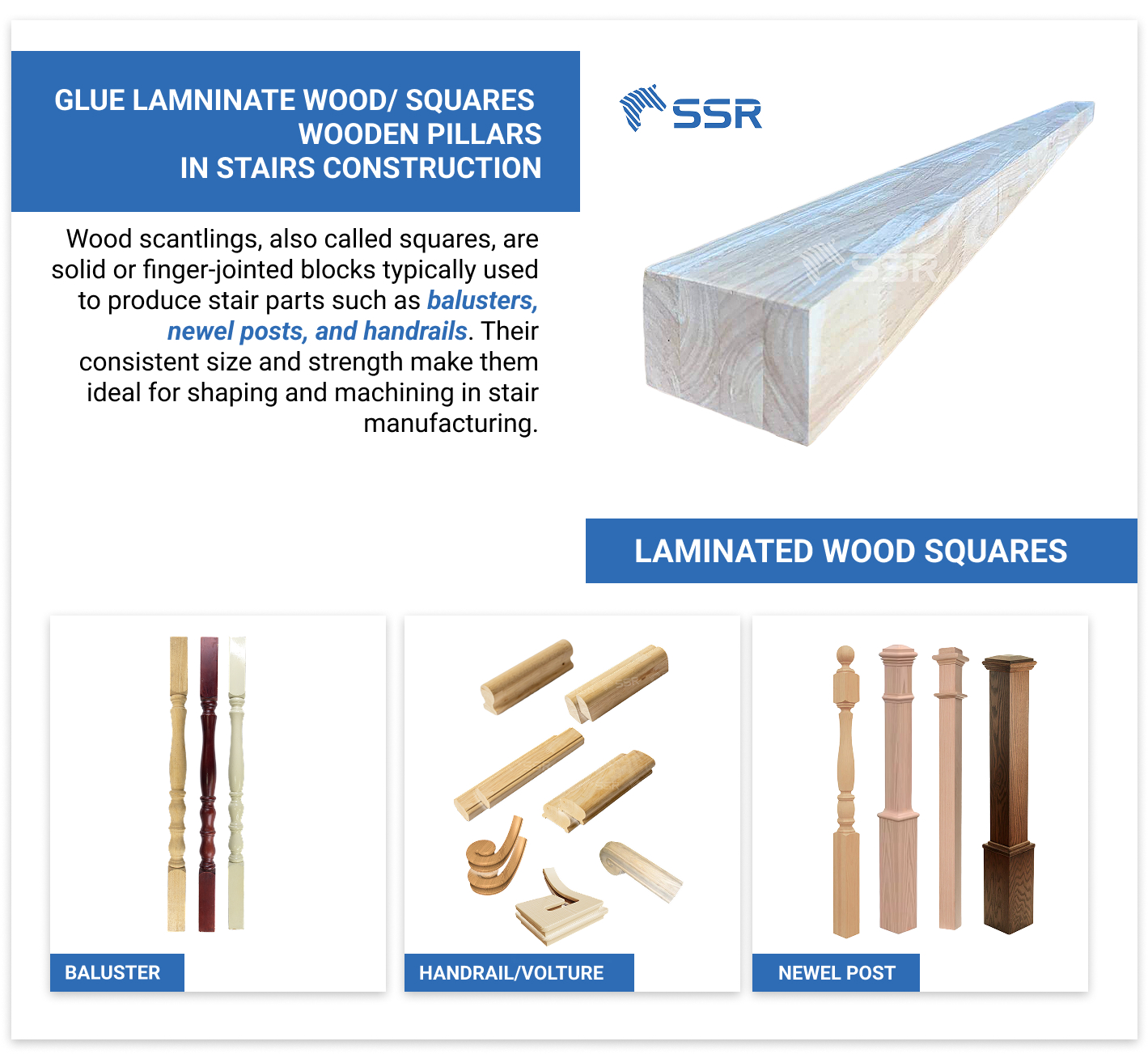

Wood Staircase

Stair Wood Material Supply by SSR Vina

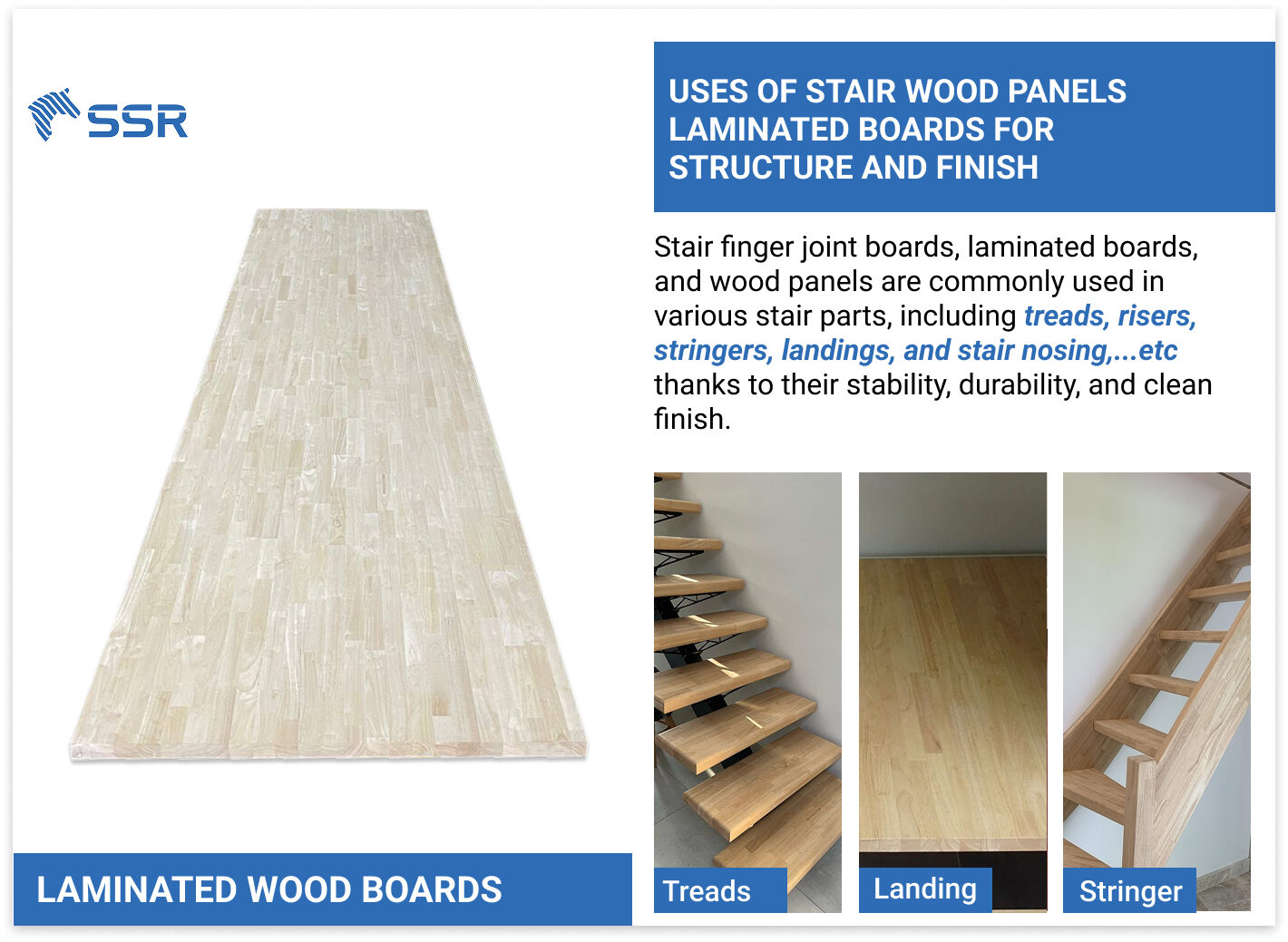

We are an international manufacturer and wholesale supplier of wood materials for stair production. We provide finger-jointed laminated boards, wooden plank, and scantlings – ideal for making treads, handrails, balusters, and more.

SSR also offers ready-made stair components upon request. Please explore our product category if you’re looking for finished treads or other parts—crafted with the same quality we bring to every board.

MATERIALS OPTIONS

RUBBER/ HEVEA

Light yellow-brown with straight, subtle grain -smooth and eco-friendly.

OAK

Golden to medium brown with bold, wavy grain and visible rays—classic and strong.

BEECH

Pale pinkish-brown with fine, straight grain-clean and easy to shape.

RUBBER/HEVEA WOOD

Rubber/ Hevea Wood Laminated Board

Specification:

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (length): 150-600 mm

- Wood Stave (width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AB or customized

- Surface Finish: sanding 240-320 grit, 2 faces

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 18 | 650/1100 | 4500/5900 |

| 22 | 650/1100 | 4500/5900 |

| 33 | 650/1100 | 4500/5900 |

| 44 | 650/1100 | 4500/5900 |

| 56 | 650/1100 | 4500/5900 |

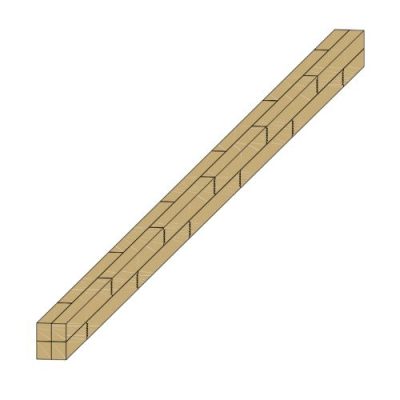

Rubber/ Hevea Wood Laminated Squares

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 55 | 55 | 4500/5100 |

| 70 | 70 | 4500/5100 |

| 85 | 85 | 4500/5100 |

WOOD JOINING TECHNIQUES

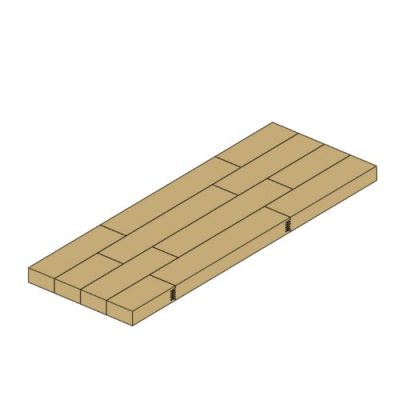

Finger Joint Board

Joining short pieces of wood using interlocking “fingers” and strong adhesive. This method creates a stable, durable board ideal for stair treads and other components.

Wood Laminated Squares

Joining short pieces of wood using interlocking “fingers” and strong adhesive. They provide strong, stable material for balusters, newel posts, handrails,…

GRADE QUALITY

At SSR Vina, we source rubberwood directly from our own certified plantations in Vietnam, ensuring consistent quality and full traceability from forest to finished panel. With careful selection and strict quality control, only the best timber is used for our panel production, resulting in a stable, attractive material with minimal waste and high visual consistency.

AA Grade Quality

Our AA Grade panels represent the highest standard, with two clean, uniform surfaces and no visible defects on at least 90% of each side. The remaining 10% may contain only minor imperfections, such as tiny black streaks or dead knots under 3mm.

AB Grade Quality

AB Grade panels offer a cost-effective alternative while maintaining a premium top surface. The front side is clear and uniform in color, suitable for visible use, while the back side may include small defects like black streaks or dead knots up to 10mm. Perfect for applications where only one side is exposed.

AC Grade Quality

This grade features one clean, visually appealing surface with minimal to no defects and uniform color tone. The reverse side may contain visible imperfections such as dark knots, cracks, or core-related flaws, including dead knots larger than 10mm in diameter.

Application

- Treads

| Thickness (mm) | 18/22/30/44 |

| Width (mm) | 140/270/300 |

| Length (mm) | 850/900/1000 |

- Stringer

| Thickness (mm) | 30 |

| Width (mm) | 270/280/340/350 |

| Length (mm) | 1200/ |

- Landing

| Thickness (mm) | 18/22/30/44 |

| Width (mm) | Customized |

| Length (mm) | Customized |

- Handrail

| Thickness (mm) | 30/46 |

| Width (mm) | 46/70 |

| Length (mm) | 1000/3100/4200/4500/5000 |

- Baluster

| Thickness (mm) | 30/32/45 |

| Width (mm) | 30/32/45 |

| Length (mm) | 825/914/950/1040/1067 |

- Newel Post

| Thickness (mm) | 70/85 |

| Width (mm) | 70/85 |

| Length (mm) | 850/950/1250 |

QUALITY CONTROL AND PACKING

Stringent Quality Standards: Committed to quality, we have a rigorous inspection and quality control process, ensuring our products adhere to international standards

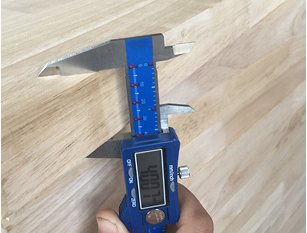

Check Moisture Content

Check Moisture Content

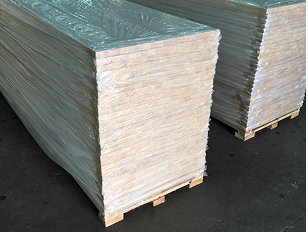

Customizable Packaging that Meets Export Standards: The products are carefully shrink-wrapped for added protection, then palletized to ensure safe and convenient shipping. Finally, the palletized goods are strategically arranged to maximize container space and maintain stability during transit.

Covering in Plastic Bag

Covering in Plastic Bag

Packing Palette

Packing Palette

MANUFACTURING CENTER

PRODUCT LINE

Rubberwood logs are sawn into boards and kiln-dried to a stable moisture content of 8–12%. After drying, the boards are inspected and cut into smaller pieces, which are then glued, pressed, and cured to form solid panels. The panels are sanded for a smooth finish and graded into AA or AB quality based on surface uniformity and minor allowable defects.

INSPIRATION

A selection of staircase designs crafted from high-quality rubberwood boards

CONTACT US

Leave your information and we will contact you for a consultation