NEWS

Crafting high-quality wood products

When it comes to crafting high-quality wood products, success begins with selecting the best raw materials. At SSR VINA, we don’t just process wood – we carefully choose it to ensure the final product meets the highest standards of durability, stability, and aesthetics. Here’s a closer look at how we meticulously select raw wood materials and uphold strict quality control from start to finish.

Selection Process for Raw Wood Materials

Raw Wood Materials

A superior wood product begins with carefully chosen raw materials. At SSR VINA, we follow a meticulous selection process to ensure that only the finest timber makes its way into our production line.

Sustainable Wood Sourcing

Sustainability

At SSR VINA, sustainability is the foundation of our wood sourcing strategy. As a company dedicated to high-quality natural solid wood, we carefully select and harvest timber from responsibly managed forests to ensure both environmental preservation and superior product quality.

We specialize in Rubberwood (Hevea Brasiliensis), Acacia, and Melia, Bamboo, prioritizing species that are renewable and have minimal ecological impact. Our Rubberwood is sourced from mature trees that have completed their latex-producing cycle typically 25 – 30 years to ensure optimal resource utilization while reducing waste. Instead of allowing these trees to be discarded or burned, we repurpose them into durable solid wood products, promoting a circular economy in forestry.

In addition, we uphold strict sustainability certifications such as FSC (Forest Stewardship Council), ensuring that our wood originates from legally and ethically managed sources. Every log is carefully inspected for quality, ensuring that our customers receive only the finest solid wood materials for furniture, construction, and interior applications.

Strict Log Classification and Inspection

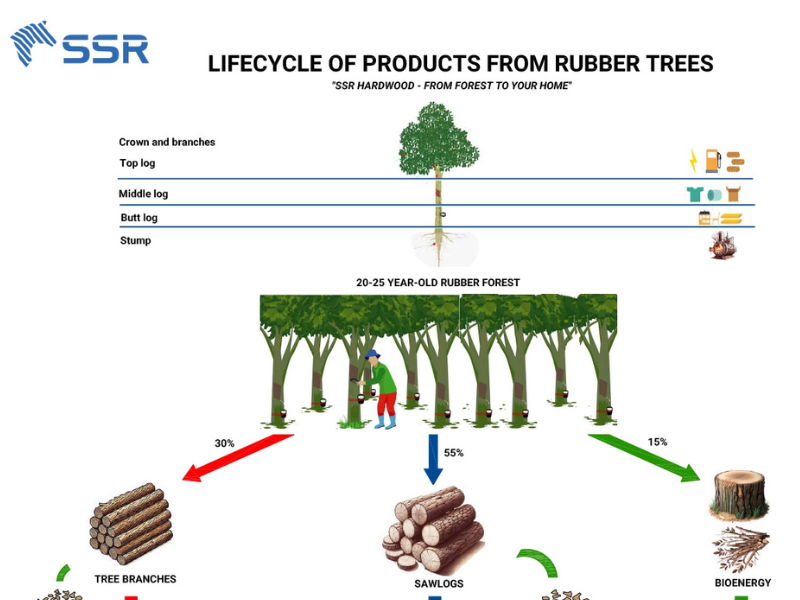

Lifecycle of products

Before entering production, each log undergoes a rigorous inspection and classification process to ensure only the highest quality wood is used. Our experts meticulously evaluate every log based on density, diameter, and structural integrity, categorizing them into butt logs, middle logs, and top logs – each suited for specific applications.

We eliminate logs with excessive knots, insect damage, cracks, or rot, ensuring that only flawless materials move forward in our production line. Logs with minor imperfections but strong internal structure may be repurposed for non-structural solid wood applications, such as small furniture components, cutting boards, or decorative wood elements, preventing unnecessary waste.

To further enhance quality, we inspect each log for moisture content, grain consistency, and uniformity, ensuring stability and durability in the final product. Additionally, we avoid using logs with excessive sap content, as this can affect adhesion in finishing processes and compromise long-term performance.

Moisture and Structural Integrity Checks

Quality Control

Wood’s moisture content and structural properties directly impact its performance and longevity. To maintain high standards, we measure moisture levels upon arrival and pre-treat logs with excessive moisture before processing. We also inspect wood grain, texture, and density to ensure uniform strength. Logs with fungal contamination or excessive sap content are rejected to meet the stringent technical requirements of furniture, flooring, and construction applications.

Ensuring Perfection: Our Quality Control Process

Strict quality control

Selecting the right raw materials is just the beginning. Maintaining strict quality control throughout every stage of production is equally critical.

- Precision Cutting & Strong Jointing Techniques: Our high-precision automated saws ensure accurate cuts with minimal deviation, reducing material waste. Advanced finger-jointing technology enhances stability and longevity by creating strong, seamless connections, while pith removal eliminates structural weaknesses for maximum durability.

- Drying for Long-Term Stability: Freshly harvested Rubberwood contains over 60% moisture, making proper drying essential. Our controlled kiln-drying process reduces moisture to an optimal 8 – 12% range, preventing warping, cracking, and mold formation. Advanced monitoring systems regulate temperature and humidity to prevent internal stresses and ensure uniform moisture distribution, eliminating post-manufacturing deformation.

Read more: https://ssr.vn/product-quality-inspection-process-of-ssr-vina/

Perfecting Surface Quality

SSR VINA’s wood

The beauty of wood lies not only in its strength but also in its flawless appearance and smooth texture. At SSR VINA, we meticulously refine every surface to ensure an impeccable finish. Through rigorous sanding, smoothing, and calibration, we create surfaces that are perfectly prepared for staining, painting, or lamination. We carefully inspect each piece for color and grain consistency, enhancing the natural aesthetics of furniture and interior applications. Any boards with surface defects, splinters, or irregular patterns are removed, guaranteeing that only the highest-quality materials reach our customers.

Final Quality Assurance Checks

Packaging and storage

Before shipping, our finished wood products undergo one last round of quality control:

- Moisture content is rechecked to confirm it meets industry standards.

- Thickness and dimensions are verified to ensure precise manufacturing tolerances.

- Packaging and storage conditions are strictly monitored to prevent damage, contamination, or humidity-related issues.

Our Commitment to Excellence

At SSR VINA, quality is non-negotiable. From selecting the finest raw wood materials to implementing rigorous quality control, every step of our process is designed to deliver outstanding wood products. Whether it’s for furniture, flooring, or construction, our wood meets the highest industry standards ensuring durability, beauty, and sustainability for years to come.

By combining innovation, sustainability, and meticulous craftsmanship, we continue to set the benchmark in the global wood industry. Looking for premium wood solutions? SSR VINA has got you covered

Featured Products

Durable Rubberwood Chevron Countertop For Kitchen Tabletop

Specification:

- Wood species: Rubberwood

- Moisture: <12 %.

- Length & Width tolerance: 0/+3 millimeters.

- Thickness tolerance: +/- 0.2 millimeters.

- Glue: D4.

- Surface finish: oil coating or sanding 240-320 grit.

- Quality: AA, AC, BC or customized

- Packing: PE plastic for each piece.

[Good Promotion] Acacia Chevron Countertop Made In Vietnam

Specification:

- Moisture: < 12%

- Wood Stave (length): 150-400 mm

- Wood Stave (width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Top Quality Acacia Edge Glued Countertop Made In Vietnam

Specification:

- Moisture: 8 -12 %

- Wood Stave (length): 150-400 mm

- Wood Stave (width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness Tolerance: +/- 0.2 mm

- Glue: D4

- Quality: ABC, AC or customized

- Surface Finish: Sanding 180-240 grit, 2 faces

Featured News

Related News

Crown Moulding for B2B Projects: Installation & Bulk Supply

Crown moulding (cornice) is more than just an architectural detail. It’s a timeless element that bridges wall and ceiling, transforming a room with subtle sophistication. Whether you’re a homeowner looking to elevate your space or a builder seeking premium finishing touches for your next project, crown moulding brings unmatched value in both form and function. In […]

How Many Types of Moulding Trim? An Essential B2B Guide

Moulding trim plays a vital role in interior finishing – bringing together form, function, and refined detail. Whether you’re sourcing materials for large-scale residential projects or customizing high-end commercial interiors, understanding the different types of skirting boards, baseboards, crown moulding, and casing trims is essential. This guide breaks down the most common moulding trim profiles […]

Tháng 5 8, 2025

Tháng 5 8, 2025 | mkt.ms-huyen

| mkt.ms-huyen

![[Good Promotion] Acacia Chevron Countertop Made In Vietnam](https://ssr.vn/wp-content/uploads/2024/12/chevcounter-3.png)