Quality Control

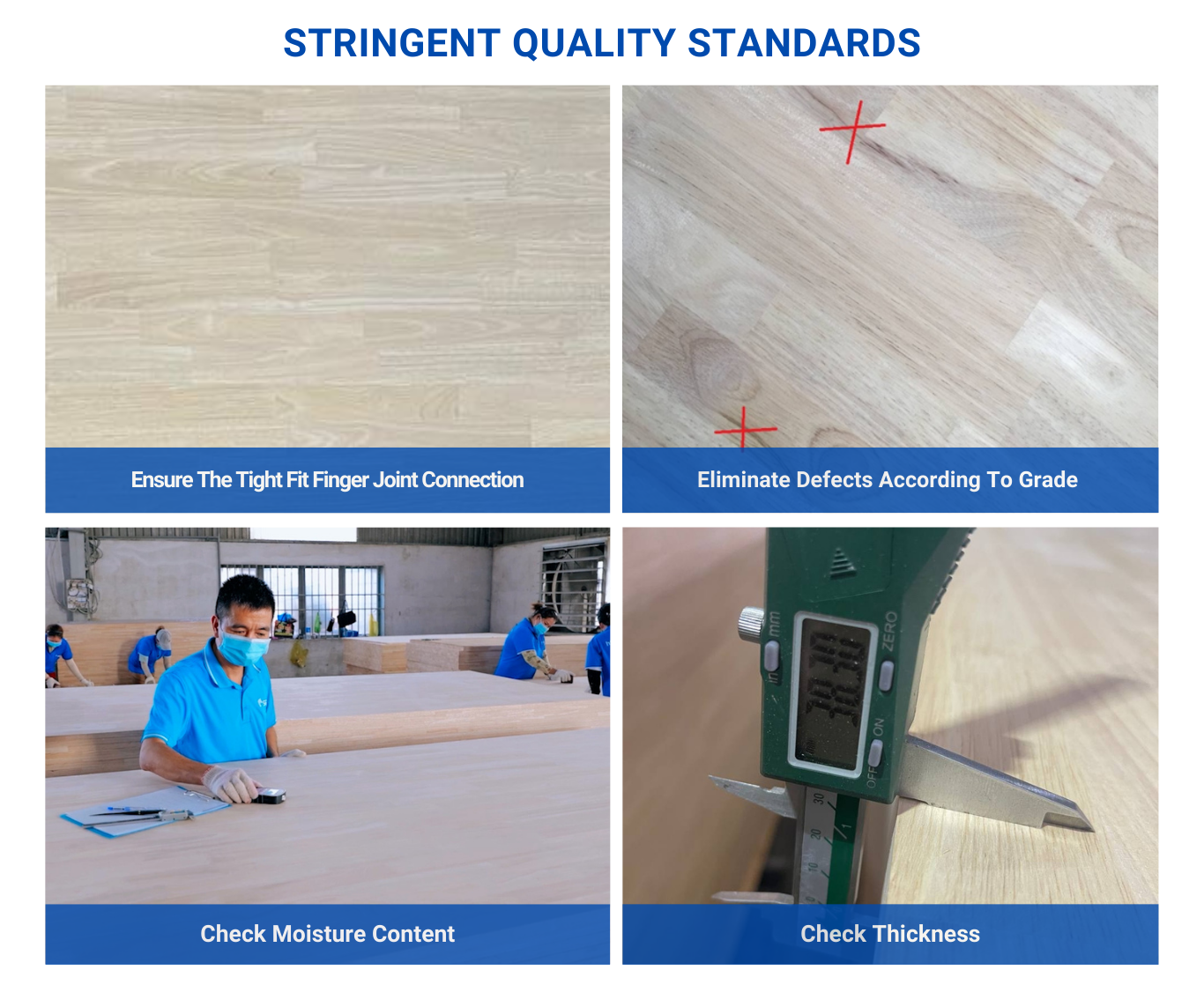

At SSR VINA, product quality is not left to chance – it is the result of a meticulous and strictly monitored quality control process, from raw materials to the finished product.

Our goal is to deliver consistently high-quality, durable, and aesthetically superior wood products to customers worldwide.

Raw Material Selection And Control

The journey begins with the careful selection of wood logs, including Acacia, Rubberwood and Beechwood . Each log is inspected for:

Size and Appearance: Logs are measured for consistent diameter, straightness, and usable volume. Only logs with minimal curvature and sufficient size for cutting standardized blanks are accepted.

Natural Defects Screening: Each log is visually inspected to identify defects such as knots, splits, cracks, insect infestation, rot, and other irregularities that could affect the strength and appearance of the end products. Logs with excessive defects are either downgraded for secondary use or rejected.

Moisture Content and Fiber Quality: Using specialized moisture meters, we ensure the logs have suitable initial moisture levels for controlled drying. Logs are also checked for tight, even grain patterns and fiber strength, which directly influence the mechanical performance of processed wood.

Raw Material Selection and Control

1.Dimension Accuracy

Each piece of wood is cut to precise thickness, width, and length standards, ensuring uniformity throughout the batch. Accurate dimensions are crucial to ensure easy further processing, minimal material waste, and seamless assembly in furniture and panel production.

2.Surface Quality Inspection

Immediately after sawing, wood blanks are inspected for surface quality. This step allows early detection and removal of defects such as rough patches, deep knots, cracks, discoloration, or surface contamination. Maintaining a clean, defect-free surface at this stage reduces the risk of imperfections affecting the final product.

3. Drying and Moisture Control

Freshly sawn wood contains high moisture, which can lead to warping, splitting, or fungal growth if not properly treated. SSR VINA uses advanced kiln-drying technology to systematically reduce the wood’s moisture content to the optimal level (typically between 8–12%, depending on the product’s end use).

Strict monitoring during drying ensures stability, longevity, and structural integrity in all finished goods.

4. Chemical Treatment

To further enhance durability, wood blanks undergo chemical treatment. This includes the application of anti-termite, anti-mold, and anti-bacterial solutions. The treatments are carefully chosen to comply with international environmental and safety standards, offering protection without compromising the natural beauty of the wood.

Grade A

High-quality wood with minimal to no defects, ideal for visible surfaces and premium furniture

Grade B

Moderate-quality wood with minor, acceptable defects, suited for less visible parts.

Grade C

Lower-grade wood used for internal structures or components where appearance is not critical.

Grade A

Grade B

Grade C

Finger Jointing and Panel Assembly

After sawing and grading, smaller wood pieces are transformed into larger, more stable panels through the finger jointing process. This method not only maximizes raw material use but also enhances the mechanical strength and dimensional stability of the final products.

SSR VINA applies strict quality control at every step of finger jointing and panel assembly to ensure world-class performance.

Finger Jointing and Panel Assembly

Final Quality Assurance Checks

Before shipping, our finished wood products undergo one last round of quality control:

Furniture Manufacturing Indoor And Outdoor

When moving into furniture production, SSR VINA’s team focuses on:

01

Design and Shape Accuracy

Ensuring compliance with original designs

Verification against master samples and technical drawings to ensure no deviations in outlines, edges, curves

02

Color Matching

Color checks against approved reference samples under standardized lighting conditions

On-site color corrections are performed immediately if any variation in tone, gloss, or depth of color

03

Structural Details

Mechanical strength tests

Measurements for squareness, flatness, and levelness are taken, adhering to specific tolerances

04

Accessories Check

Verification against technical drawings

Accessory quality checks

Compatibility assessment

05

Final Product Quality Control

Measuring Dimensions

Surface Quality Check

Moisture Content Verification

Packaging Quality

Through a comprehensive and closely monitored quality control system, SSR VINA guarantees that each piece of wood from raw log to finished product – reflects our commitment to excellence. This rigorous process ensures that customers receive products of superior craftsmanship, environmental responsibility, and lasting beauty.