NEWS

Rubberwood finger joint board is considered a type of product that is a matching material for kitchen countertops. In fact, they are less costly than other materials such as natural stone (granite), engineered stone (quartz), or other textures with a solid surface.

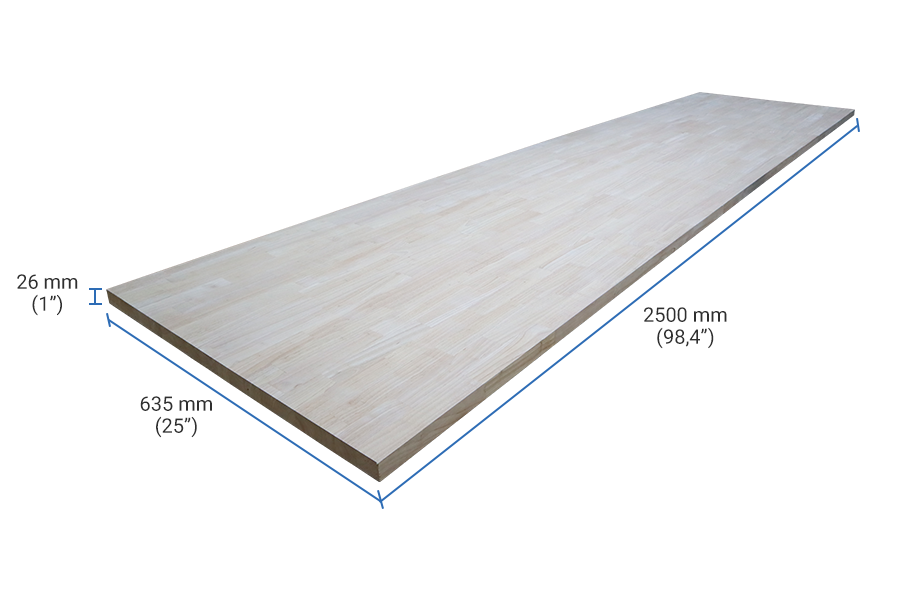

The above rubberwood panel would cost nearly (price), less than a solid surface

The difference between a wooden kitchen and a granite counter is the sound. You can check this by putting your dinnerware on each one and then hearing, a wooden kitchen is less noisy.

A rubberwood panel has a natural grain model that can easily differentiate from man-made materials. Some householders say that the grain pattern in rubberwood seems to be less “personality” and a bit tedious. Homeowners are in preference for other premium hardwoods over rubberwood.

On the modern and advanced technology production lines, short wooden sticks having the same width but different lengths are jointed into the bars of equal length and then jointed parallel depending on the requirements of the size of the panel width.

The hardness of a wood is rated on an industry-wide standard known as the Janka test. Rubberwood is classified as “moderately hard” at 4,280 N. For comparison, Janka hardness of teakwood at 4,740 N. As a result, a rubberwood kitchen countertop is able to cope with regular kitchen use without any issues.

See more product: Rubberwood/ Hevea Butcher Block Kitchen Countertop

The wooden kitchen countertop is easily exposed to standing water or extreme heat. For example, condensation or hot temperature might leave a mark on it, caused by defrosting fish or putting a hot pan.

To prevent wood from getting damaged by sun and heat, to use a wood protector. Oil, is a wood protector, moisturizes the wood and seals it, to keep it in moisture so the wood can last longer.

The finished surface of the rubberwood finger joint board can be coated with an oil or UV layer in order to increase its aesthetics and durability.

Featured Products

Acacia Wood Butcher Block Countertops Supplier

Specifications:

- Species: Acacia

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 30-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Birch Butcher Block Countertop Supplier

Specifications:

- Species: Birch

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Featured News

Related News

Bamboo Cutting Board Tips for Distributors – SSR VINA

Bamboo has become a popular alternative to traditional hardwoods when it comes to kitchen cutting boards. But is it really a good choice for your kitchen? In this guide, we’ll cover everything from the benefits and downsides to care instructions, environmental impact, and FAQs. What is a Bamboo Cutting Board? A bamboo cutting board is […]

Biomass Energy: The Natural Powerhouse of Renewable Energy

In the search for sustainable energy solutions, biomass stands out as one of the most promising alternatives to fossil fuels. But what exactly is biomass, and why is it gaining attention around the world? Let’s explore how this natural energy source works, where it’s used, and what the future holds. What Is Biomass? Biomass refers […]