NEWS

Pine Finger Joint board goes along with the development orientation and provides high-quality products of SSR VINA, making the interior design and construction work more professional.

What is Pine Finger Joint Board?

Pine Finger Joint Board is a high-quality wood product made from radiata pine or Merkusii pine. This material is crafted using an advanced finger-jointing technique, where small wooden bars are connected with strong D4 glue. The result is a durable, stable, and water-resistant board that retains its natural beauty. The surface can be finished with paint or left in its original state, allowing for versatile design applications. The production process ensures efficiency in raw material use, reducing waste while maintaining structural integrity.

Pine wood used in this product is carefully selected to meet high standards in both aesthetics and durability. Each piece undergoes thorough treatment to enhance its resistance to environmental factors, such as humidity and temperature changes. This guarantees that the boards remain strong and long-lasting, making them an excellent choice for various construction needs. Additionally, the sustainable nature of pine wood makes it a responsible option for those who prioritize eco-friendly building materials.

Why has Pine Finger Joint Board become trendy in interior construction?

Providing excellent durability and aesthetic appeal, Joint Board from Pine has gained popularity in interior construction. It withstands heavy loads without warping and maintains its color over time. The material is lightweight, easy to work with, and eco-friendly, as it optimizes raw wood utilization. With its natural warmth and charm, this product enhances the look of modern and traditional interiors alike.

Practicality is another reason for its rising popularity. Compared to solid wood, joint board from Pine wood offers a more cost-effective solution without compromising quality. The ability to join smaller wood pieces into a single, uniform board minimizes waste and maximizes efficiency. Furthermore, the strong adhesion between the finger joints prevents cracks and deformation, ensuring that furniture and structures retain their shape for years.

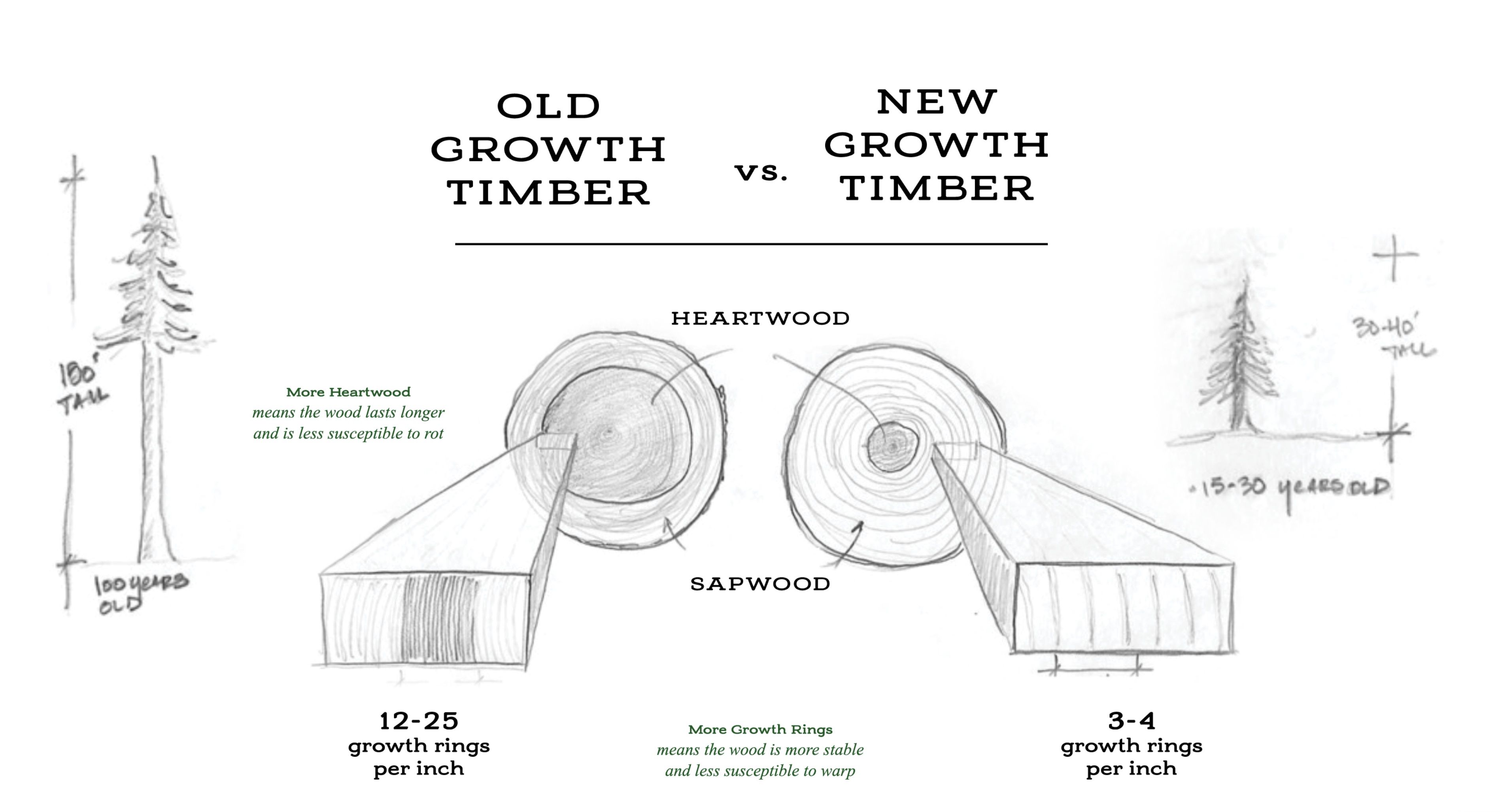

The development of old pine and new pine by Brent Hull

The flexibility of design also makes pine wood a preferred choice among architects and interior designers. Whether used for contemporary minimalist interiors or classic rustic designs, its adaptability allows for a wide range of creative applications. The ability to stain or paint the surface adds another layer of customization, making it suitable for any aesthetic preference.

What is Pine Finger Joint Board applied for in interior construction?

Practicality and versatility make pine wood suitable for various interior applications. It is widely used for furniture such as tables, cabinets, and shelves, adding a natural and sophisticated touch to spaces. Wall and floor cladding made from this board brings a spacious and luxurious feel to homes and offices. Additionally, it is ideal for large structural components like door frames, partitions, and factory frameworks.

Seater Sofa from Modest Furniture

Pine Finger Joint Board’s adaptability means it is used in a variety of settings, from residential homes to commercial spaces. In modern home designs, it is frequently incorporated into built-in furniture, creating seamless and aesthetically pleasing storage solutions. Many designers prefer it for open shelving, allowing homeowners to display decorative pieces while maintaining a cohesive look.

For larger construction projects, this material proves invaluable in the creation of sturdy partitions and framework components. Factories and office buildings benefit from its stability and strength, ensuring a reliable structure that stands the test of time. Additionally, its excellent moisture resistance makes it a practical choice for areas exposed to humidity, such as kitchens and bathrooms.

How does SSR VINA produce it with high quality?

Strict quality control ensures that every Pine Finger Joint Board produced by SSR Vina meets international standards. Using advanced technology, the company sources pine wood from sustainable forests, maintaining a moisture content of 8-12% for optimal durability. With a monthly production capacity of up to 4000m³, SSR Vina guarantees a steady supply of premium wood products. The company also provides expert consultation, helping customers choose the most suitable materials for their projects.

SSR Vina’s production process includes several critical steps to ensure quality and consistency. The wood undergoes careful selection, cutting, and drying to achieve the ideal moisture balance. Finger-jointing technology is then applied to create seamless connections between wood pieces, reinforcing the board’s strength and stability. Once assembled, each board is meticulously sanded and treated to enhance its appearance and durability.

The commitment to sustainable practices is another defining feature of SSR Vina’s production approach. By using responsibly sourced pine wood and minimizing waste, the company actively contributes to environmental conservation. Customers can trust that they are investing in a product that aligns with green building principles while delivering outstanding performance in interior construction. For more information, visit SSR Vina to explore the range of quality products.

Featured Products

Acacia Wood Butcher Block Countertops Supplier

Specifications:

- Species: Acacia

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 30-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Birch Butcher Block Countertop Supplier

Specifications:

- Species: Birch

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Featured News

Related News

SSR at Hawa Expo 2026: Scaling excellence to global markets

Consistency in the global wood industry is the result of large-scale capacity and meticulous coordination. SSR is proud to announce our official participation in HAWA EXPO 2026, driven by a serious commitment to showcase the strength of our integrated ecosystem. This event is a milestone for us to prove that enterprises can fully master the […]

Bamboo Cutting Board Tips for Distributors – SSR VINA

Bamboo has become a popular alternative to traditional hardwoods when it comes to kitchen cutting boards. But is it really a good choice for your kitchen? In this guide, we’ll cover everything from the benefits and downsides to care instructions, environmental impact, and FAQs. What is a Bamboo Cutting Board? A bamboo cutting board is […]