NEWS

How to recognize quality finger jointed boards in a market that has many suppliers and its quality. How to recognize quality wooden boards in a market in which the suppliers have much various qualities. Each supplier will provide their customer with different standards. Therefore, let’s take a look at a standard of our product qualities, which has been trusted by customers over the years.

1. Evaluate the surface quality of the finger joint wood panel to suit your needs

We aim for wood boards that meet the customer’s requirements for technical standards and diverse product specifications.

First, the surface of wooden boards is classified into different A, B, C quality standards based on the criteria of defect rate and color.

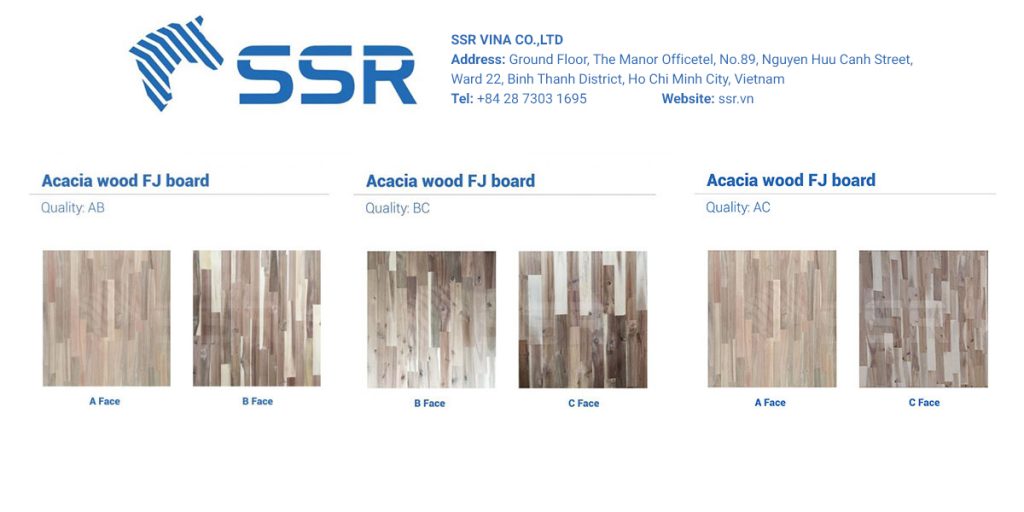

+ Acacia wood finger jointed boards

Face A: Highest quality surface with little sapwood, and virtually no defects.

Face B: Second quality surface with some sapwood and defects

Face C: Third-quality surface with unlimited sapwood and defects.

+ Rubberwood finger jointed boards

Face A: Highest quality surface with uniform color and virtually no defects.

Face B: Second quality surface with discolouration, some acceptable defects.

Face C: Third quality surface with discolouration, and unlimited number of defects.

To optimize the use, finger jointed boards are combined with surface qualities such as AC, BC, AB. The higher quality surface will be used as the main face. This brings aesthetics to interior products, makes the most of raw materials, and saves costs for customers.

Before joining into finished boards, they will go through the stage of sorting the workpiece. This is an important step to help ensure board quality and reduce the percentage of unsatisfactory boards. Therefore, we will deliver exactly your quality requirements depending on the type of required surface

2. Choose the finger jointed board’s color according to the color palette

The color palette helps clients to have more choices of color tones to suit consumer tastes. This creates a unique difference among distributors so they serve customers with their distinctive color gamut.

The advantage of oiled or UV-coated finger jointed boards is to limit external influences on wooden boards such as water entering, the heat burning the surface of the board, or scratching.

However, these inevitable situations are affected by the external environment. Therefore, it is necessary to maintain and clean the surface well over wood board’s lifetime

It is good to pay attention to the maintenance of the wood surface after the time of sanding and creating a new coating. This ensures long-term durability of the product.

3. Applications of finger jointed boards

– To meet the increasing needs of customers, we always focus on the quality criteria of wooden boards.

First, wooden boards ensure the required aesthetics with the level of color uniformity, and the defect rate of the surface as committed. The rough surface is completely sanded and smoothed so it meets certain aesthetic requirements for the processing and finishing of the interior.

Second, to meet the requirements of technique. In manufacturing process, we require board no any errors are impossbile. However, thanks to the proactive monitoring through each production stage, the error rate can be partially assessed in the process from raw materials to the final products. Therefore, there will be a step of final selection before packing in order to ensure the bearing capacity and durability of the wood board well.

– With a variety of specifications associated with size, thickness, color. We have the ability to meet the multiple needs of finger jointed boards manufacturing and construction in an international market including Europe, America, Asia, etc.

– Wood boards have the advantage is that it still retains the characteristics of each type of wood such as: wood grain, sapwood (with clearly distinguishable core and inlaid woods like Melaleuca). Therefore, it owns a natural beauty and is eco-friendly.

See More Products: Pros and cons of rubberwood finger joint board for kitchen

Featured Products

Durable Rubberwood Chevron Countertop For Kitchen Tabletop

Specification:

- Wood Species: Rubberwood (Hevea brasiliensis)

- Moisture: <12 %.

- Length & Width Tolerance: 0/+3 millimeters.

- Thickness Tolerance: +/- 0.2 millimeters.

- Glue: D4.

- Surface Finish: Oil coating or sanding 240-320 grit.

- Quality: AA, AC, BC, or customized

- Packing: PE plastic for each piece.

[Good Promotion] Acacia Chevron Countertop Made In Vietnam

Specification:

- Moisture: < 12%

- Stave Length: 150-400 mm

- Stave Width: 20-80 mm

- Length & Width Tolerance: 0/+3 mm

- Thickness Tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC, BC, or customized

- Surface Finish: Sanding 180-240 grit, both faces.

Top Quality Acacia Edge Glued Countertop Made In Vietnam

Specification:

- Moisture: 8 -12 %

- Stave Length: 150-400 mm

- Stave Width: 20-80 mm

- Length & Width Tolerance: 0/+3 mm

- Thickness Tolerance: +/- 0.2 mm

- Glue: D4

- Quality: ABC, AC, or customized

- Surface Finish: Sanding 180-240 grit, both faces

Featured News

Related News

Crown Moulding for B2B Projects: Installation & Bulk Supply

Crown moulding (cornice) is more than just an architectural detail. It’s a timeless element that bridges wall and ceiling, transforming a room with subtle sophistication. Whether you’re a homeowner looking to elevate your space or a builder seeking premium finishing touches for your next project, crown moulding brings unmatched value in both form and function. In […]

How Many Types of Moulding Trim? An Essential B2B Guide

Moulding trim plays a vital role in interior finishing – bringing together form, function, and refined detail. Whether you’re sourcing materials for large-scale residential projects or customizing high-end commercial interiors, understanding the different types of skirting boards, baseboards, crown moulding, and casing trims is essential. This guide breaks down the most common moulding trim profiles […]

Tháng 6 28, 2023

Tháng 6 28, 2023 | SSR

| SSR

![[Good Promotion] Acacia Chevron Countertop Made In Vietnam](https://ssr.vn/wp-content/uploads/2024/12/chevcounter-3.png)