NEWS

Pre-primed finger joint wood board is commonly used in residential and commercial construction projects. Primed finger joint wood board is the preferred choice because it is ready for construction and installation, helping to save costs, and has a variety of sizes and designs to meet customer requirements. Let’s discover more about the product and the benefits it brings.

1. What is a primed finger joint board?

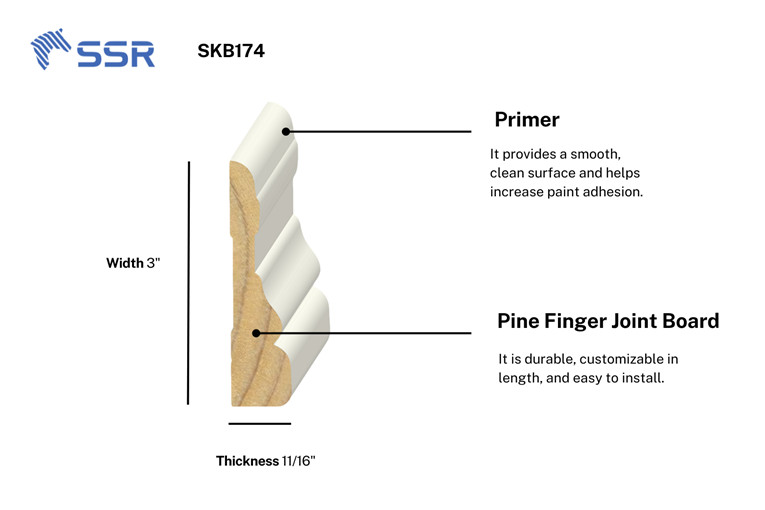

Primed finger joint board is a highly effective product used for construction projects. The material of the Primed finger joint board is from pine wood, a wood material that is flexible and easy to construct.

The finished products have primer. It helps add an extra layer of protection against moisture, insects, and pests. At the same time, it helps make the paint cover layer more durable and beautiful.

Primed finger joint panel products are made from small staves providing seamless, straight, and stable lengths for applications such as decoration, molding, cladding, etc. The finger joint structure brings durability and stability. Primed finger joint panels are the ideal choice for construction projects. Easily install and create attractive and elegant spaces with primed finger joint boards.

2. The benefits of Finger joint primed board structure

The finger joint primed board structure offers many significant benefits for decorative and construction applications. Firstly, the finger joint structure allows the creation of customized length boards, up to 6m, helping to meet the custom requirements of decorative projects such as baseboards, molding, and construction projects.

Another benefit of this structure is its ability to limit the warping of the boards. Thanks to finger jointing and hydraulic pressure, the board structure will be highly stable, limiting warping and reducing defects in the panel.

The finger joint structure is jointed from small pieces of staves by vertical “finger joints” and glue, then horizontally jointed together by hydraulic pressure with standard sizes or can be customized as customer requirement.

The finger joint structure has the advantage of optimizing wood usage, costs, and natural and sustainable wood materials.

Using a finger joint primed board structure not only brings benefits in terms of the ability to meet special requirements for product size and features but also helps optimize material use and ensure durability for decorative and construction applications.

3. The benefits of pre-primed finger joint board

Primed finger joint boards are necessary steps in the product finish process to bring many significant benefits.

First, Pre-priming saves time and work for the installation process because the finished project requires priming and painting. In this way, the board is primed and ready for complete construction.

The priming process is manufactured in a mass-production environment to ensure consistency and quality for each product. It helps ensure uniformity in the texture and finish of the product, thereby creating uniform aesthetics and quality.

The primer enhances aesthetics and adds an extra layer of protection to the wood. It helps protect the wood from external factors such as weather and humidity.

Paint adhesion is also significantly improved when using primer. It helps the wood surface smooth and clean and increases paint adhesion, making the finished paint layer more uniform and durable.

Finally, Primed finger joint boards help create a seamless, knot-free finished product. Primer not only brings aesthetics to the product but also prolongs the life of the paint layer, keeping the product always new and durable over time.

4. The advantages of Trim board primed finger joint include a variety of sizes and applications

There are a variety of sizes, applications, and designs of trim board primed finger joints that bring many advantages to interior decoration projects.

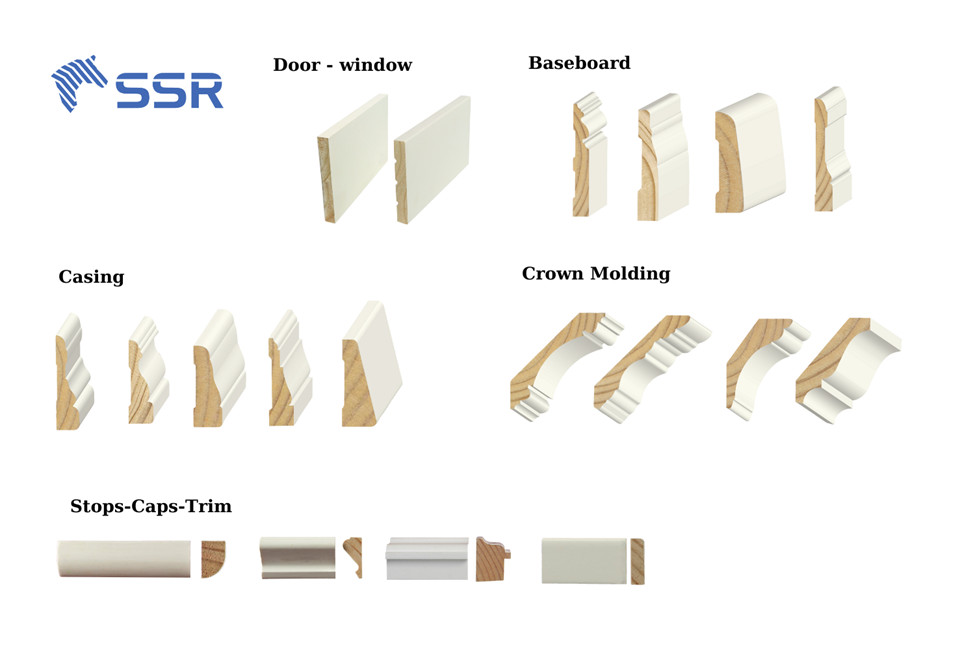

The primed finger joint boards are pre-manufactured in various sizes, from width to length to thickness, responding to every project. The boards are for specific purposes, such as baseboards, crown molding, door casings, and window trim.

Types of available molding meet many different decorative molding and trim purposes. The trim board primed finger joint can be flexibly applied to most interior design styles, from classic to modern, elegant, and liberal.

In terms of application, these primed finger joint boards are often used for sophisticated and luxurious interior decoration. They can be applied accent details such as baseboards, crown molding, door casings, and window trims. In particular, precise machining and smooth finishing give interior details cleanliness, adding beauty and value to living spaces.

In short, Trim board primed finger joint not only bring flexibility and ease in selection and use but also create diverse and luxurious interior decoration solutions for every project.

5. SSR VINA primed finger joint board

SSR VINA brings customers primed finger joint board products manufactured according to requirements. We mainly supply primed finger joint boards from pine wood, with the surface finished with S4S primer. Outstanding features of the product are its durability and good paint-adhering surface, ready for customers to paint according to preferences.

With a mass production process using modern machinery and many years of experience in the industry, we are committed to providing customers with finished products that meet high-quality standards.

At the same time, we provide flexible customization products, meeting customers’ requirements of size and style, thereby making their projects more diverse. SSR VINA is always committed to bringing satisfaction and trust to customers through quality products and professional services.

Read More:

Featured Products

Durable Rubberwood Chevron Countertop For Kitchen Tabletop

Specification:

- Wood Species: Rubberwood (Hevea brasiliensis)

- Moisture: <12 %.

- Length & Width Tolerance: 0/+3 millimeters.

- Thickness Tolerance: +/- 0.2 millimeters.

- Glue: D4.

- Surface Finish: Oil coating or sanding 240-320 grit.

- Quality: AA, AC, BC, or customized

- Packing: PE plastic for each piece.

[Good Promotion] Acacia Chevron Countertop Made In Vietnam

Specification:

- Moisture: < 12%

- Stave Length: 150-400 mm

- Stave Width: 20-80 mm

- Length & Width Tolerance: 0/+3 mm

- Thickness Tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC, BC, or customized

- Surface Finish: Sanding 180-240 grit, both faces.

Top Quality Acacia Edge Glued Countertop Made In Vietnam

Specification:

- Moisture: 8 -12 %

- Stave Length: 150-400 mm

- Stave Width: 20-80 mm

- Length & Width Tolerance: 0/+3 mm

- Thickness Tolerance: +/- 0.2 mm

- Glue: D4

- Quality: ABC, AC, or customized

- Surface Finish: Sanding 180-240 grit, both faces

Featured News

Related News

Crown Moulding for B2B Projects: Installation & Bulk Supply

Crown moulding (cornice) is more than just an architectural detail. It’s a timeless element that bridges wall and ceiling, transforming a room with subtle sophistication. Whether you’re a homeowner looking to elevate your space or a builder seeking premium finishing touches for your next project, crown moulding brings unmatched value in both form and function. In […]

How Many Types of Moulding Trim? An Essential B2B Guide

Moulding trim plays a vital role in interior finishing – bringing together form, function, and refined detail. Whether you’re sourcing materials for large-scale residential projects or customizing high-end commercial interiors, understanding the different types of skirting boards, baseboards, crown moulding, and casing trims is essential. This guide breaks down the most common moulding trim profiles […]

Tháng 3 27, 2024

Tháng 3 27, 2024 | Mkt.anhtruc

| Mkt.anhtruc

![[Good Promotion] Acacia Chevron Countertop Made In Vietnam](https://ssr.vn/wp-content/uploads/2024/12/chevcounter-3.png)