NEWS

When it comes to wood products for furniture, cabinetry, or interior finishes, one term you’ll often encounter are finger joint wood boards. But what exactly is it, and why should you choose a reliable finger joint wood board supplier like SSR VINA? Let’s dive into everything you need to know.

What Is a Finger Joint Wood Board?

What is a finger joint wood board

Finger joint boards are a type of engineered wood product created by joining multiple shorter pieces of solid wood end-to-end using precision-cut, interlocking “fingers.” These fingers are shaped like a zigzag or comb pattern, resembling clasped hands when connected. Once the joints are coated with industrial-grade adhesive and pressed together, they form a longer, seamless board that is strong, stable, and visually uniform.

This method of construction is highly efficient because it makes use of off-cuts and shorter wood sections that might otherwise be discarded. As a result, finger joint boards are not only cost-effective, but also environmentally friendly, as they help reduce wood waste and support sustainable production practices.

What Kind of Wood Is Used for Finger Joint Wood Board?

What kind of wood is used for finger joint wood board

Finger joint wood boards can be manufactured using a variety of wood species, depending on the application, desired aesthetics, durability requirements, and budget. The flexibility of the finger jointing process allows manufacturers to work with both hardwoods and softwoods, including reclaimed or shorter-length lumber that would otherwise go to waste. Here are some of the most commonly used wood types:

-

Rubber Wood

Rubber wood is one of the most popular choices for finger joint boards due to its sustainability, affordability, and versatility. It comes from rubber plantations where trees are harvested after their latex-producing cycle ends—typically after 25–30 years. Rubber wood is light-colored, moderately dense, and easy to work with, making it ideal for furniture, interior panels, and kitchenware. It also accepts stains and paints well, making it a favorite in both natural and coated finishes.

Read more: https://ssr.vn/what-is-hevea-wood/

-

Acacia

Acacia is a hardwood known for its remarkable strength, durability, and attractive grain patterns. Its natural resistance to wear and moisture makes it suitable for premium furniture, countertops, and decorative elements. When used in finger joint boards, acacia combines aesthetic appeal with mechanical performance, offering a high-end look with added dimensional stability.

-

Pine

Pine is a lightweight, softwood species that’s easy to process and widely available. It’s often used in construction, moldings, and interior trim due to its straight grain and ease of painting. Finger jointed pine boards are frequently used for baseboards and door casings, as the finger joints eliminate natural defects like knots and warping while maintaining a uniform appearance.

-

Hardwoods (e.g., Oak, Teak, Ash)

Premium hardwoods like oak, teak, and ash are sometimes used in finger joint boards for high-end applications. These woods offer exceptional strength, beautiful textures, and natural resistance to insects or decay. While more expensive, hardwood finger joint wood boards are prized in luxury furniture, cabinetry, and architectural finishes where performance and aesthetics are both top priorities.

-

Other Regional Species

In some regions, local wood types such as eucalyptus, meranti, or birch may be used, depending on availability and suitability. These species can offer competitive quality and sustainability benefits when processed correctly.

At SSR VINA, we specialize in rubber wood and acacia wood finger joint wood boards, ensuring durability and eco-friendliness in every product.

What Is a Finger Joint Wood Board Commonly Used For?

What is a finger joint board commonly used for

Finger joint wood boards are known for their versatility, strength, and consistent appearance, making them a favorite in both residential and commercial woodworking. Thanks to their stability and sustainability, they are used in a wide range of applications, including:

1. Furniture Manufacturing

Finger joint boards are often used to make tables, chairs, bed frames, drawers, wardrobes, and more. Their smooth surface and uniform texture make them easy to paint, veneer, or laminate.

Cost-effective without compromising strength, they’re ideal for large-scale furniture production.

2. Interior Panels and Wall Cladding

Used for decorative wall panels, ceiling lining, or accent walls, especially in modern or minimalist interiors. The clean, uniform look provides a contemporary aesthetic while also improving acoustic and thermal insulation.

3. Door and Window Frames

Door and window frames

Finger joint wood is a popular choice for door jambs, window casings, and shutters. Its stability helps prevent warping or cracking, which is essential in areas exposed to fluctuating temperatures and humidity.

4. Baseboards and Moldings

Ideal for skirting boards, crown molding, and trim work, finger joint wood boards allow for long, straight runs without knots or defects. They’re easy to install and paint, making them a go-to for interior finish carpentry.

5. Kitchen Cabinets and Shelves

Kitchen cabinets and shelves

Frequently used in cabinet carcasses, shelves, and panel doors, finger joint wood offers the perfect balance of strength, workability, and aesthetics. Suitable for both exposed and hidden areas due to its customizable finish.

6. Stair Parts and Handrails

Stair parts and handrails

The strength and joinery quality of finger joint wood boards make them a reliable material for stair treads, risers, stringers, and handrails. They can be stained or painted to match a variety of interior styles.

7. Countertops and Worktops

When laminated into thicker panels, finger joint wood boards can be used for kitchen counters, workbenches, or island tops, especially in rustic or natural-themed interiors.

8. Shelving Systems

Great for floating shelves, display units, and bookcases, especially in modular or DIY-style furniture.

What Is the Strength of Finger Joint Wood Boards?

What is the strength of finger joint wood board

Unlike butt joints or simple glued ends, finger joints distribute stress evenly across multiple contact points. This makes them less prone to splitting or breaking under load or impact. Additionally, the engineered nature of finger jointed wood allows manufacturers to select and combine the most stable, defect-free wood segments, eliminating weak points caused by knots, cracks, or grain irregularities.

Strength Benefits of Finger Jointed Wood:

- High load-bearing capacity, especially in compression and tension along the length

- Excellent dimensional stability, minimizing warping, cupping, or twisting over time

- Uniform strength distribution, reducing the chance of failure at specific points

- Suitable for structural and decorative use, including furniture, doors, and frames

What Is the Weakness of Finger Jointed Wood?

Finger joint wood boards

While finger joint wood boards are durable, they have a few limitations:

- Not suitable for high-moisture environments unless treated or coated

- Visible joint lines may affect aesthetics in natural finishes

- Improper gluing or poor craftsmanship can lead to joint failure

Why Choose a Finger Joint Board?

Why choose a finger joint board

Finger joints wood boards are not just practical — they’re economical and sustainable:

- Reduce wood waste by using shorter, leftover pieces

- Offer greater dimensional stability compared to solid wood

- Lower cost without compromising quality

- Support sustainable forestry by maximizing raw material usage

How to Make Finger Joint Wood Boards?

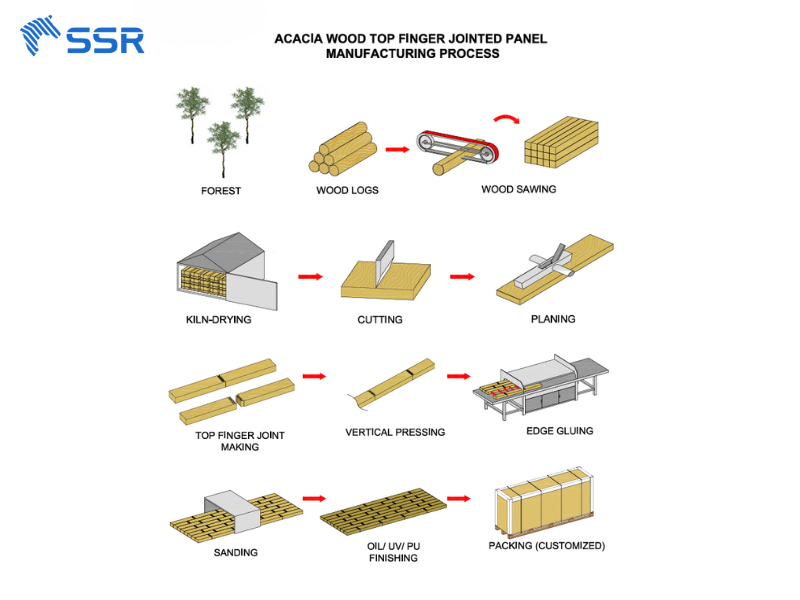

Acacia wood top finger jointed panel manufacturing process

1. Forest – Plantation Harvesting

Acacia trees are grown in managed and sustainable plantations. Once they reach harvest age (typically 5–7 years), the trees are cut down for processing.

Acacia wood is fast-growing, straight-grained, and ideal for finger joint panels.

2. Wood Logs – Raw Logs

After harvesting, trees are cut into logs of appropriate lengths.

These logs are pre-sorted by diameter, quality, and curvature before sawing.

3. Wood Sawing – Primary Sawing

Logs are sawn into rough-sawn timber strips using industrial sawmills.

The dimensions depend on the desired specifications of the final panel product.

4. Kiln-Drying

Sawn timber is dried in a kiln to reduce moisture content from 40–60% down to 8–12%. This is a crucial step to:

- Prevent mold and insect infestation

- Minimize warping, cracking, and shrinking

- Improve dimensional stability

5. Cutting

After drying, timber is cut into short lengths (typically 20 – 50 cm). Cutting helps remove wood defects such as dead knots, cracks, or insect damage to ensure quality.

6. Planing

The wood strips are planed for smooth, uniform surfaces and accurate dimensions. This ensures:

- Better adhesive bonding

- Precise finger jointing

- Enhanced visual appeal

7. Top Finger Joint Making

The ends of the short strips are shaped into finger joints using specialized machinery. These joints are glued together with industrial adhesives (commonly PUR or PVAc). This process extends the timber length and optimizes raw material usage.

8. Vertical Pressing

The finger-jointed strips are vertically pressed to ensure strong bonding under heat and pressure. This creates long, stable timber pieces suitable for panel production.

9. Edge Gluing

The long timber strips are edge-glued side by side to form full-width panels. A horizontal press ensures a flat, well-bonded panel surface.

10. Sanding

The glued panels are sanded in multiple stages to create a smooth and even surface. Sanding improves surface quality for finishing and ensures aesthetic consistency.

11. Oil/ UV/ PU Finishing

Depending on customer requirements, panels may receive one of the following finishes:

- Oil: for a natural, eco-friendly appearance

- UV Coating: for scratch resistance and UV protection

- PU Coating: for a glossy look and protection against moisture and light chemicals.

This finishing enhances durability and visual quality.

12. Packing (Customized)

Finished panels are packaged using shrink wrap, pallets, or cartons according to buyer specifications. Each package is labeled with product information and batch details for quality control and shipment tracking.

SSR VINA – Your Trusted Finger Joint Wood Board Supplier

SSR VINA your trusted finger joint wood board supplier

With years of experience and a strong commitment to sustainability, SSR VINA is a leading finger joint wood board supplier in Vietnam and global markets. We offer:

- High-quality acacia and rubberwood boards

- Customized sizes and finishes

- FSC-certified wood products

- Competitive pricing and on-time delivery

- A transparent and professional sourcing process

Whether you’re a furniture manufacturer or a construction material buyer, you can rely on SSR VINA for consistent quality and long-term partnership.

FAQs

Can finger joint wood be used outside

Can finger joint wood be used outside?

Yes, if properly sealed or coated, finger joint wood boards can be used in outdoor settings. However, untreated boards are best reserved for indoor use.

Is finger jointed lumber cheaper?

Yes. Finger joint wood boards are more cost-effective than solid wood because they use smaller wood pieces that would otherwise go to waste.

Is finger jointed lumber better than solid wood?

For certain applications, yes. Finger jointed lumber is more stable, sustainable, and affordable, though solid wood may still be preferred for visible natural grain aesthetics.

What does a finger joint look like in wood?

It resembles a series of zigzag interlocking cuts at the ends of two wood pieces, glued to form a seamless extension.

Can you nail into baseboard?

Yes, finger joint wood boards are strong enough to be nailed or screwed into baseboards, trims, and moldings.

Can you use finger joint wood boards for baseboards?

Absolutely. Their smooth finish and consistent dimensions make them a popular choice for baseboards and decorative trim.

Conclusion

Finger joint wood boards offer the perfect combination of strength, sustainability, and cost-efficiency. Whether you’re crafting fine furniture or finishing a modern interior, working with a trusted finger joint wood board supplier like SSR VINA ensures you get the best in quality and service.

Contact SSR VINA today and explore our full range of premium finger joint wood solutions.

Featured Products

Acacia Wood Butcher Block Countertops Supplier

Specifications:

- Species: Acacia

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 30-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, BC or customized

- Surface finish: Sanding 180-240 grit, 2 faces

Rubberwood Finger Joint Board Supplier

- Species: Rubberwood

- Moisture: <12 %

- Wood Stave (Length): 150-600 mm

- Wood Stave (Width): 35-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AA, AC or customized

- Surface Finish: sanding 240-320 grit, 2 faces

Birch Butcher Block Countertop Supplier

Specifications:

- Species: Birch

- Moisture: < 12%

- Wood Stave (Length): 150-400 mm

- Wood Stave (Width): 20-80 mm

- Length & Width tolerance: 0/+3 mm

- Thickness tolerance: +/- 0.2 mm

- Glue: D4

- Quality: AB, AC or customized

- Surface finish: Sanding 180-240 grit, 2 faces.

Featured News

Related News

SSR Wood in Tay Ninh: Groundbreaking a New Production Hub

SSR held the groundbreaking ceremony for its new wood processing facility in Tay Ninh on November 28. The plant is expected to produce 2,000 cubic meters per month. The project represents a significant expansion of SSR’s manufacturing capacity in Southern Vietnam and will operate as part of the Ho Chi Minh production area, one of […]

SSR VINA becomes VCCI Member: A New Milestone

SSR VINA is proud to announce its official VCCI member (Vietnam Chamber of Commerce and Industry) – the nation’s leading organization representing the business community and employers in Vietnam. This marks a significant milestone in SSR VINA’s journey to enhance the global presence of “Made-in-Vietnam” products, reaffirming our commitment to quality, innovation, and sustainable growth. […]

Tháng 5 12, 2025

Tháng 5 12, 2025 | mkt.ms-huyen

| mkt.ms-huyen